Actueel

Brusselle in de kijker

Today, we want to give a big shout out on 𝙒𝙤𝙧𝙡𝙙 𝘾𝙤𝙢𝙥𝙡𝙞𝙢𝙚𝙣𝙩 𝘿𝙖𝙮 to the incredible engineers at #Brusselle who made it all possible! 🙌

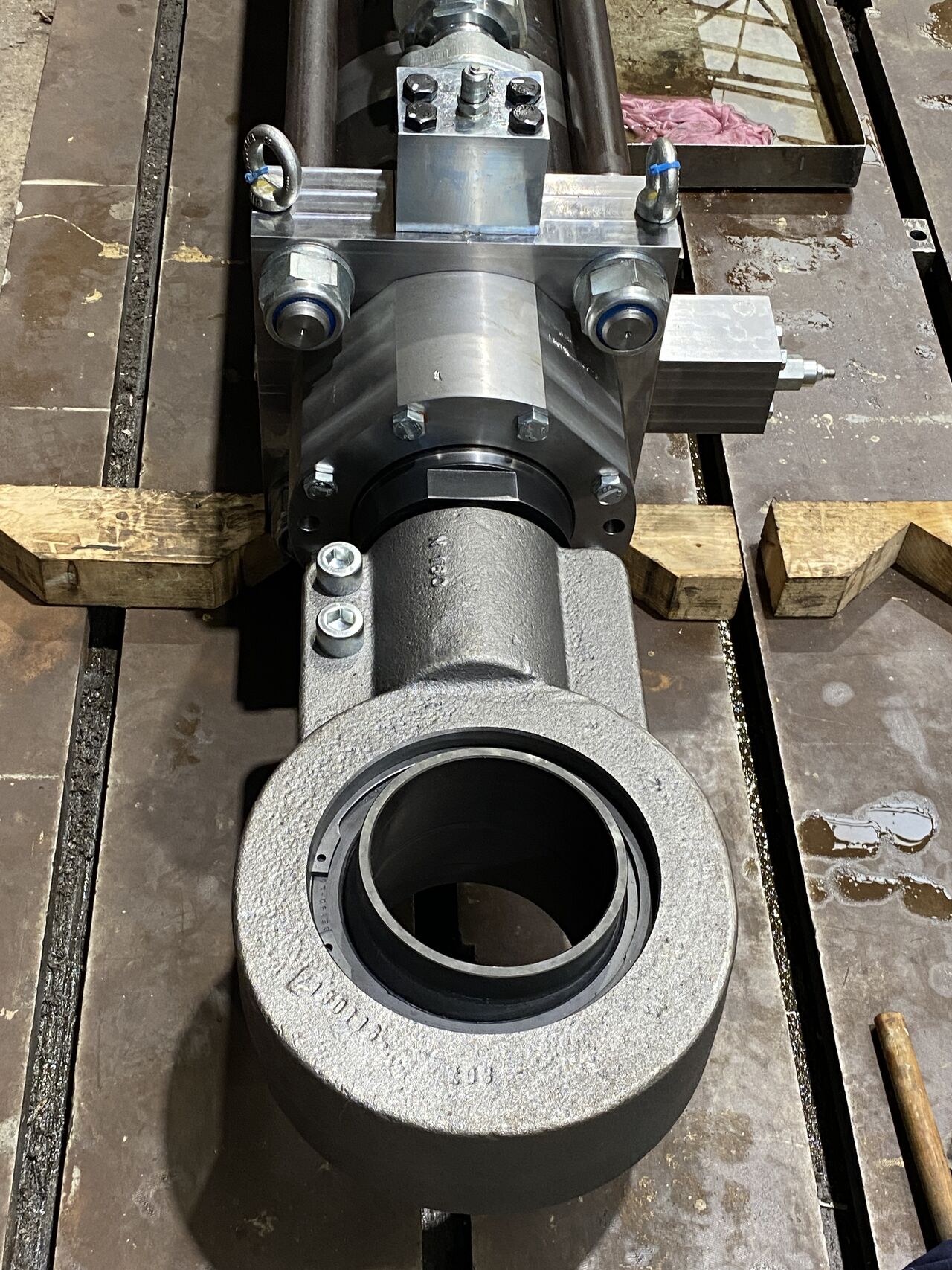

Their dedication and expertise were instrumental in getting our 𝙣𝙚𝙬 𝙙𝙤𝙪𝙗𝙡𝙚 𝙨𝙩𝙚𝙚𝙧𝙞𝙣𝙜 𝙜𝙚𝙖𝙧 𝙨𝙮𝙨𝙩𝙚𝙢 for a newbuild dredging ship approved by both our valued customer and the 𝙘𝙡𝙖𝙨𝙨𝙞𝙛𝙞𝙘𝙖𝙩𝙞𝙤𝙣 𝙗𝙤𝙙𝙞𝙚𝙨 involved.

🔧 This robust steering gear system, designed and assembled by our engineers, boasts a working 𝙩𝙤𝙧𝙦𝙪𝙚 of 386 kNm x2 and an operating 𝙧𝙪𝙙𝙙𝙚𝙧 𝙖𝙣𝙜𝙡𝙚 of 2x 60°. In a mere 10 seconds, the rudders can smoothly transition from 35° to 30° portside to starboard.

💪 With two 𝙙𝙤𝙪𝙗𝙡𝙚-𝙖𝙘𝙩𝙞𝙣𝙜 𝙘𝙮𝙡𝙞𝙣𝙙𝙚𝙧𝙨, each precisely acting on one rudder tiller, our system is ready for optimal performance. And let’s not forget about our powerhouse of a 𝙥𝙤𝙬𝙚𝙧𝙥𝙖𝙘𝙠, featuring two hydraulic main pumps and one emergency pump.

👏 Let’s give a round of applause to our dedicated team for their outstanding work! Together, we’re steering towards excellence. 🌟

#Engineering #TeamWork #Brusselle #SteeringGear #Robustness #Quality #SuccesfulFAT #WorldComplimentDay

Excited to share this look inside our workshop in Zeebrugge! 🛠️

Featuring two declutchable split #drums, each with a working and storage part, and a pneumatically controlled friction-clutch on the main shaft, this #hydraulic towing #winch with a 65 Ton bollard pull has been delivered with pump units and control units. 🔄

The gearbox and end-pedestals, secured directly by #heavyduty blocks with pin and eye fixation, eliminate the need for an extra lining-out procedure after mounting. 📐

#Brusselle #TowingWinch #winches #engineering #quality #assembly #zeebrugge

⚓ Witness the installation of main gear wheels with the assistance of our bridge crane. Each 𝙜𝙚𝙖𝙧𝙬𝙝𝙚𝙚𝙡, weighing 270 kg and boasting a diameter of 807 mm, plays a crucial role in the 𝙙𝙧𝙞𝙫𝙚 𝙢𝙚𝙘𝙝𝙖𝙣𝙞𝙨𝙢 𝙤𝙛 𝙩𝙝𝙚 𝙘𝙝𝙖𝙞𝙣𝙬𝙝𝙚𝙚𝙡 𝙤𝙧 𝙨𝙥𝙧𝙤𝙘𝙠𝙚𝙩.

Highlighting the importance of #quality assurance, these main gear wheels are made from forged material, accompanied by a 3.2 material #certificate to guarantee reliability and performance.

Proud to showcase our commitment to quality during winch assembly!

#Winches #Assembly #WorkshopLife

#Brusselle #Engineering #Quality #Certification 🛳️